You’ll review six cage-nut tools for IT racks and compare how each handles M4–M10 nuts, 10″ or 19″ racks, and front, side, or top access. Start with the RackSolutions tool for rubber grip and angled neck, then the Kwmobile model, then the 2-pack QWORK tool, followed by the rotatable options, and finish with the 4-pack QWORK set. Consider grip, weight, materials, and jaw action to fit your setup, and choose the best fit to tackle fast, secure cage-nut insertions and removals.

| RackSolutions Cage Nut Tool with Rubber Grip Angled Neck |

| Best Ergonomic | Purpose: Cage nut installation/removal tool | Rack Compatibility: 10″ and 19″ racks (general data center racks) | Cage Nut Sizes Supported: M6 (inside thread), also supports various brands | VIEW LATEST PRICE | Read Our Analysis |

| Kwmobile Cage Nut Tool for Network Racks |

| Adjustable Ease | Purpose: Cage nut insertion/removal tool | Rack Compatibility: 10″ and 19″ network/rack cabinets | Cage Nut Sizes Supported: M4, M5, M6 | VIEW LATEST PRICE | Read Our Analysis |

| QWORK Cage Nut Insertion/Removal Tool (2 Pack) |

| Pair-Value Deal | Purpose: Cage nut insertion/removal tool | Rack Compatibility: 19″ and 10″ server racks | Cage Nut Sizes Supported: M4, M5, M6 | VIEW LATEST PRICE | Read Our Analysis |

| Rotable Cage Nut Tool for IT Server Racks |

| Rotable Precision | Purpose: Cage nut tool for front/side/top installation/removal | Rack Compatibility: IT/Data Center racks (front/side/top) | Cage Nut Sizes Supported: M4, M5, M6, M8, M10 | VIEW LATEST PRICE | Read Our Analysis |

| QWORK Cage Nut Insertion/Removal Tool 4 Pack |

| Multi-Pack Value | Purpose: Cage nut insertion/removal tool | Rack Compatibility: 10″ and 19″ server racks | Cage Nut Sizes Supported: M4, M5, M6 | VIEW LATEST PRICE | Read Our Analysis |

| Rotable Cage Nut Tool for IT Racks (M4–M10) |

| Wide-Range Versatility | Purpose: Rotable cage nut tool for installation/removal | Rack Compatibility: IT/data center racks (10″–19″ compatibility implied) | Cage Nut Sizes Supported: M4, M5, M6, M8, M10 | VIEW LATEST PRICE | Read Our Analysis |

More Details on Our Top Picks

RackSolutions Cage Nut Tool with Rubber Grip Angled Neck

The RackSolutions Cage Nut Tool with Rubber Grip Angled Neck stands out for its angled neck that lets you access back-of-rack cage nuts from outside the rack, which is essential in dense rack environments. You read the tool’s purpose, grip the rubber handle, and align with the cage nut. Squeeze, hook, tilt, and release to install quickly. If a brand doesn’t fit, use the tool’s wide compatibility with XOOL, Lancher, ACInfinity, and others. Do not use Ubiquiti cage nuts. Verify dimensions, 6 mm inside thread, and right-hand thread. Practice in a test rack before live deployment.

- Purpose:Cage nut installation/removal tool

- Rack Compatibility:10″ and 19″ racks (general data center racks)

- Cage Nut Sizes Supported:M6 (inside thread), also supports various brands

- Operating Style:Manual squeeze/tilt/press

- Material Type:Metal with powder coating

- Ergonomics/Safety:Rubber grip; ergonomic design

- Additional Feature:Wide brand compatibility

- Additional Feature:Angled neck access

- Additional Feature:Rubber grip comfort

Kwmobile Cage Nut Tool for Network Racks

Kwmobile Cage Nut Tool for Network Racks stands out for its adjustable compatibility, letting you fit M4, M5, and M6 cage nuts in both 10″ and 19″ rack formats. You use it by placing the cage nut in the tool jaws, then squeezing the sides to insert or remove it from the hole. It works with 10″ and 19″ network racks, delivering fast installation and removal for M4, M5, M6 cage nuts. Material is aluminium, reducing finger injuries and rack damage. For use, align nut, insert, and remove as needed, repeating for each nut in the cabinet.

- Purpose:Cage nut insertion/removal tool

- Rack Compatibility:10″ and 19″ network/rack cabinets

- Cage Nut Sizes Supported:M4, M5, M6

- Operating Style:Manual squeeze operation

- Material Type:Aluminum

- Ergonomics/Safety:Aluminum with safety/anti-injury focus

- Additional Feature:Adjustable screw-fit

- Additional Feature:10″ and 19″ racks

- Additional Feature:Aluminum body

QWORK Cage Nut Insertion/Removal Tool (2 Pack)

If you want a reliable, two‑pack tool set for quick cage-nut work, the QWORK Cage Nut Insertion/Removal Tool stands out for its adjustable fit and safe operation. You use it to install or remove cage nuts in 19‑inch or 10‑inch racks, cabinets, and IT gear. The tool is hand‑operated and safe, protecting the rack frame and your hands. To use it, place the lock nut in the tool jaws, then squeeze to insert. It adjusts for M4, M5, or M6 nuts by changing screw size. Made of premium aluminum, it’s anti‑corrosion and durable; the 2‑pack stays ready.

- Purpose:Cage nut insertion/removal tool

- Rack Compatibility:19″ and 10″ server racks

- Cage Nut Sizes Supported:M4, M5, M6

- Operating Style:Hand-operated squeeze

- Material Type:Premium aluminum

- Ergonomics/Safety:Anti-corrosion aluminum; safe to use

- Additional Feature:2 pack set

- Additional Feature:Premium aluminum

- Additional Feature:Anti-corrosion durability

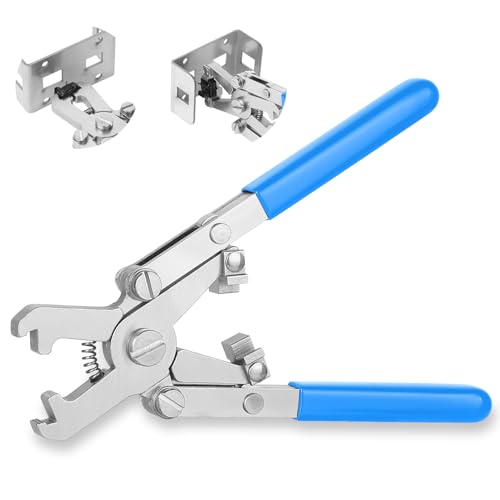

Rotable Cage Nut Tool for IT Server Racks

Rotable Cage Nut Tool for IT Server Racks centers on its dual-head, rotatable design that handles front, side, and top cage-nut work in a single tool. You can use the rotatable clip pliers to install or remove nuts on sides or top, and switch to the spring-loaded pliers head for front installation or removal. It supports M4, M5, M6, M8, and M10 nuts, and uses durable high-carbon steel with ergonomic rubber grips to reduce fatigue. The tool stabilizes with a spring mechanism, preventing screw loosening, while its two flip-access designs provide angle flexibility for tight spaces. Safety and support accompany purchase.

- Purpose:Cage nut tool for front/side/top installation/removal

- Rack Compatibility:IT/Data Center racks (front/side/top)

- Cage Nut Sizes Supported:M4, M5, M6, M8, M10

- Operating Style:Rotable dual-head pliers with flip design

- Material Type:High-carbon steel

- Ergonomics/Safety:Rubber grips; hand protection

- Additional Feature:Two plier heads

- Additional Feature:Rotatable clip pliers

- Additional Feature:Spring-loaded mechanism

QWORK Cage Nut Insertion/Removal Tool 4 Pack

The QWORK Cage Nut Insertion/Removal Tool, 4 Pack stands out for IT pros who regularly install or remove cage nuts in 19-inch and 10-inch racks. You use it to install or extract cage nuts in server racks and cabinets. It works with M4, M5, and M6 nuts by adjusting the screw size. Place the lock nut in the tool jaws, squeeze sides, and insert into the hole. It protects the frame from damage and guards you from sharp tools. It fits 10-inch and 19-inch rails, and the tool is premium aluminum, anti-corrosion, durable for long-term use.

- Purpose:Cage nut insertion/removal tool

- Rack Compatibility:10″ and 19″ server racks

- Cage Nut Sizes Supported:M4, M5, M6

- Operating Style:Manual squeeze operation

- Material Type:Premium aluminum

- Ergonomics/Safety:Aluminum with safety protection

- Additional Feature:4-pack quantity

- Additional Feature:M4/M5/M6 adjustment

- Additional Feature:Aluminum construction

Rotable Cage Nut Tool for IT Racks (M4–M10)

This Rotable Cage Nut Tool stands out for its dual-head, rotatable plier design, which lets you insert cage nuts from the front and remove them from the sides or top without changing tools. You select the two plier heads, flip the rubber grip to switch modes, and use the spring-loaded head for front insertion. For side or top removal, rotate the pliers and apply outward pressure. It fits cages for M4–M10 nuts and grips 2–2.5 cm easily. Made of high-carbon steel with ergonomic grips, it reduces fatigue and protects hands during repetitive rack work.

- Purpose:Rotable cage nut tool for installation/removal

- Rack Compatibility:IT/data center racks (10″–19″ compatibility implied)

- Cage Nut Sizes Supported:M4, M5, M6, M8, M10

- Operating Style:Rotable dual-head pliers with two-head design

- Material Type:High-carbon steel

- Ergonomics/Safety:Rubber grips; ergonomic and protective design

- Additional Feature:Wider nut range

- Additional Feature:Rubber grip ergonomics

- Additional Feature:Front/rear operation modes

Factors to Consider When Choosing Cage Nut Tools for IT

When choosing cage nut tools, assess Ergonomic Grip Design to reduce hand fatigue during frequent use. Check Tool Compatibility Range and Nut Size Versatility to ensure the tool fits the rack hardware you work with, and verify a Rotable/Two-Head System for flexibility in tight spaces. Prioritize Durability and Safety by looking for solid construction and protective features, and compare models that meet these criteria with practical, real-world examples.

Ergonomic Grip Design

Are you selecting cage nut tools that minimize fatigue during long installs? Choose an ergonomic grip design first. Prioritize rubberized or textured grips to prevent slipping and improve control when squeezing and manipulating tool jaws. Check for a comfortable diameter and contour that fit your hand without cramping during repeats. Look for an angled neck or rotatable head to reach rear-facing cage nuts without awkward body positioning. Verify weight is around 8–9 ounces to minimize hand strain over long sessions. Confirm that the grip supports long-duration tasks in dense rack environments, promoting precision and safety. Test several models, compare grip texture, and ensure smooth jaw action. Select the tool that balances grip comfort, reach, and lightness for consistent performance.

Tool Compatibility Range

Can you ensure your cage nut tool fits a range of sizes and rack formats before you buy? Check explicit compatibility labels for cage nut sizes like M4, M5, M6, M8, and M10, and verify if the tool covers your needs. If a model offers adjustable screw-fit mechanisms, confirm it can span a size range (for example M4–M6) and test with a sample nut. Note rack format compatibility: look for tools designed for 10-inch or 19-inch racks and identify whether front, side, or top installation is supported. Consider rotable or multi-head designs to access different angles, expanding use across configurations. Material matters too; aluminum or high-carbon steel affects durability and applicability across sizes. Match build to your environment and follow manufacturer guidance for best results.

Nut Size Versatility

Nut size versatility is essential for a cage nut tool you’ll rely on across different rack systems. You should choose tools that support multiple cage nut sizes, from M4 to M10, covering common 4–10 mm thread options. Look for adjustable or interchangeable screw-fit compatibility so one tool handles different nut types without extra adapters. A wider compatibility range, up to M10, reduces the need for additional tools when upgrading racks. Prefer tools labeled adjustable or rotatable, as they accommodate a broader mix of cage nut dimensions and insertion angles. Verify explicit compatibility for both front and side/top installation angles to fit various rack configurations. Follow these checks during evaluation to ensure versatile, future‑proof performance.

Rotable/Two-Head System

Rotable or two-head cage nut tools let you reach front, side, and top positions without swapping tools. You use two plier heads with a rotatable mechanism to access installation and removal angles. A flip-able rubber grip lets you switch between head orientations for different rack-access scenarios. Spring-loaded heads help maintain grip on nuts during insertion and removal, reducing drops or slips in dense racks. Wide angle capability, typically 2–2.5 cm nut compatibility, enables handling M4–M10 cage nuts across multiple rack positions. The tool combines ergonomic, high-carbon steel construction with rubber grips to minimize technician fatigue during large deployments and repairs. Choose a model with secure rotation and reliable spring tension to ensure stable operation in tight spaces.

Durability and Safety

Durability and safety start with material choice and grip design. Choose tools made from high-carbon steel or premium aluminum for repeated use without quick wear. Inspect grips: rubber handles and ergonomic shapes reduce fatigue and improve control during extended cage nut tasks. Look for a rotatable or multi-head design to access front, side, or top without losing grip, minimizing slippage and hand injury risk. Ensure the tool has a spring-loaded mechanism to maintain stable grip and prevent drops or misalignment during operation. Check compatibility range: aim for models supporting M4–M10 nuts and 2–2.5 cm widths to cover most cages. Verify finish, corrosion resistance, and smooth movement of jaws to support durable performance under frequent use in IT racks.

Final Thoughts

You’re choosing a cage nut tool for IT racks, so pick one that fits your needs. Start with compatibility: ensure it covers M4–M10 and both 10″ and 19″ racks. Decide on grip and weight: rubberized grips and about 8–9 oz reduce fatigue. Consider versatility: rotatable, two-head designs, and spring-loaded jaws for secure operation. Compare sets: 2-pack, 4-pack, or single tool. Lastly, confirm brand reliability and test on your rack prior to full use.

Meet Ry, “TechGuru,” a 36-year-old technology enthusiast with a deep passion for tech innovations. With extensive experience, he specializes in gaming hardware and software, and has expertise in gadgets, custom PCs, and audio.

Besides writing about tech and reviewing new products, he enjoys traveling, hiking, and photography. Committed to keeping up with the latest industry trends, he aims to guide readers in making informed tech decisions.